GREEK LEADER PETROLEUM COMPANY CHOOSES CONCRETE CANVAS

The works were carried out by Perendes Technologies - Anelixis Constructions for Elin Oil Hellenic Petroleum Company SA, with consultation services provided by PowerServe Ltd Greece.

In July 2017, Concrete Canvas® GCCM* (CC) was used for bund lining at a petroleum tank farm in Athens, Greece. The existing bunds of the petroleum tank farm were subject to weathering and erosion affecting the ground’s integrity and failure of stability. The client required a long-term, durable and cost-effective solution to combat the issue.

In addition, Athens is subject to extremely hot weather in summer months, with temperatures often hitting highs of 48 degrees, which was putting the heavily vegetated bunds in danger of causing fires. As a result, a weed suppression solution was also required to prevent fires on the site, which could be incredibly dangerous on a site containing highly flammable fuel.

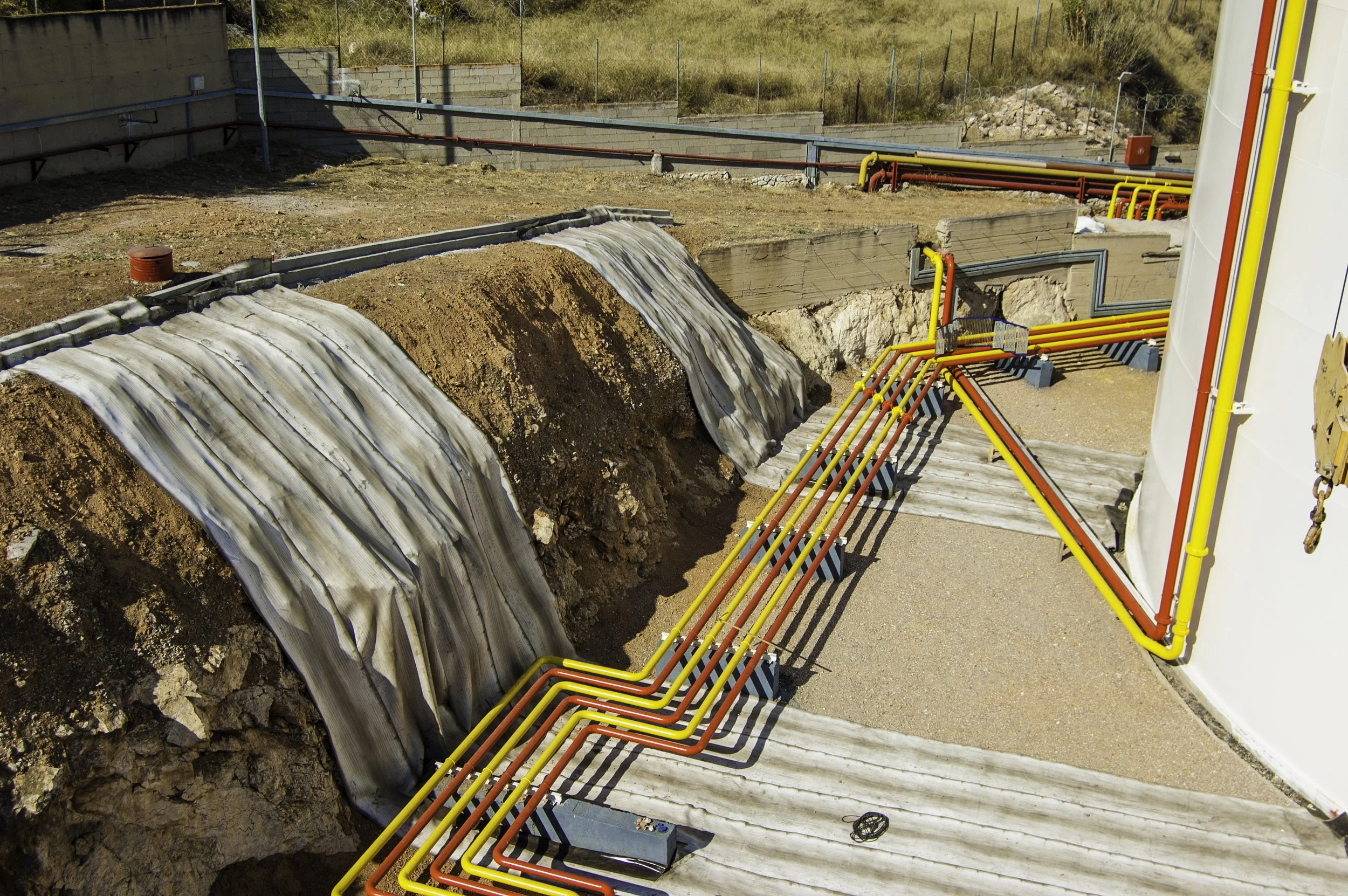

The chosen solution also had to be easily installed without interfering with the existing complex pipe infrastructure, while providing stability to infrastructure site-wide. Traditional concrete combined with Shotcrete was considered; however, there was a risk of rebound from shotcrete affecting the infrastructure and site environment, whereas CC would be totally safe and would provide a clean install. There were also site access issues, and traditional concrete methods would have required the use of heavy plant on site, which would not have been possible. As a result, CC was specified.

The existing bunds had been affected by weathering erosion, Heavy vegetation growth was at risk of causing fires in the summer heat, A solution was required that could accommodate the complex pipework

In preparation for the installation, all vegetation, rocks and debris were removed, and the ground re-levelled. Bulk rolls of CC5TM were then delivered to site, mounted onto a spreader beam and lifted using a crane to the crest of the bund slope. The CC was then unrolled, guided by two of the installation team, down the length of the slope, and two others continued to unroll the CC along the tank floor with the same continuous layer.

delivery on site

CC5 (5mm thick) was delivered to site in bulk rolls mounded onto a spreader beam deployed by a crane.

The CC was fixed at the crest to a concrete slab poured for this project using masonry nails. This process was repeated along the length of the slope, with additional layers overlapping by 100mm. Each overlap was sealed using Everbuild Clearfix adhesive sealant, and jointed using Hilti collated screws at 50mm intervals down the slope, and at 200mm intervals along the tank floor.

The slope’s rocky surface was drilled and 12mm x 170mm anchor bolts were inserted along with 12mm x 250mm J pegs to secure the material to the slope, and then the floor surface. For the other end of the material, where it meets the wall, the same method was used, fixing the CC onto the existing concrete infrastructure using masonry nails

“6,400 SQM of CC5TM were installed in 9 days”

Infrastructure such as the petroleum storage tanks and pipework were easily accommodated due to the drape characteristics and flexibility of CC. The CC around the walls of the storage tanks, corners and other complex shapes from protruding infrastructure, was cut using hand tools, and where needed, an extra layer of CC was fitted around the item, then sealed. Once the installation was complete, the CC was hydrated using hoses attached to fire pipes. This was repeated three times due to the high temperatures of around 45 degrees on site, to ensure adequate hydration.